PRODUCT

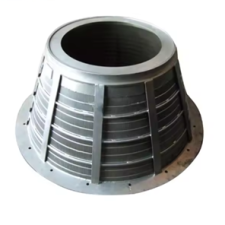

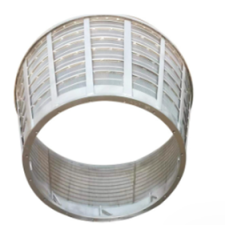

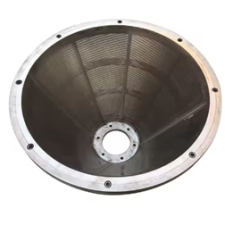

Centrifuge Sieve Basket

Material: stainless steel wire

Features: 1. Structural design: The sieve basket is usually composed of an upper flange, a lower flange, reinforcing ribs, a reinforcing ring, and a stainless steel conical mesh cylinder. This structural design allows it to withstand vibration and impact during high-speed rotation.

- Material selection: The sieve basket is generally made of metal mesh or plastic mesh, with different pore sizes. Users can choose the appropriate sieve according to their actual needs.

- Wear and corrosion resistance: The sieve basket is made of highly wear-resistant and corrosion-resistant materials, which can resist foreign object damage, reduce maintenance rates, and extend service life.

- Filtration effect: The screen gap design of the sieve basket is reasonable, not easy to block, has a large flow area, and has a good filtration effect.

Usage: The centrifuge screen basket is mainly used for separating and filtering solid particles or other impurities suspended in liquids. It plays a key role in industries such as coal, chemical, metallurgy, especially in centrifugal dewatering equipment.

Material | Stainless steel wire |

Bar size | 0.75×1.5,2×4,3×6,2x10mm |

Wire diameter | 0.5×1,0.75×1.5,2×3,3x5mm |

Hole shape | slotting |

Slot size | 0.01mm-20mm |